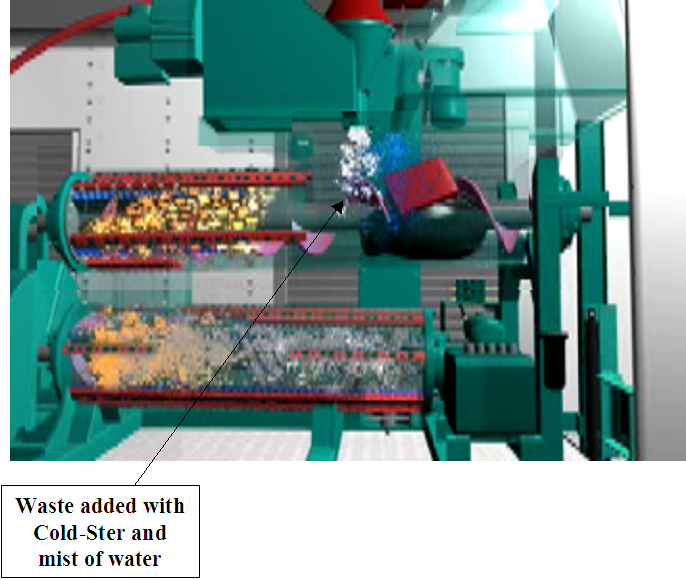

For a mobile unit, PIWS personnel will take the facilities waste from the facility’s holding area to the processing staging area. For a on-site unit, the medical facilities personnel will load the unit as the waste is received. Once the unit is prepared for processing, the medical waste stored in the containers is transferred to the on-board feed hopper. Only the medical waste produced by the facility is actually weighed in the hopper.

For a mobile unit, PIWS personnel will take the facilities waste from the facility’s holding area to the processing staging area. For a on-site unit, the medical facilities personnel will load the unit as the waste is received. Once the unit is prepared for processing, the medical waste stored in the containers is transferred to the on-board feed hopper. Only the medical waste produced by the facility is actually weighed in the hopper.

The PIWS-3000’s on-board computer captures all required information for permanent and regulatory records.

The PIWS-3000’s on-board computer captures all required information for permanent and regulatory records.Mailing Address

Corporate Office

Positive Impact Waste Solutions

PO BOX 1725

Paramus, New Jersey 07653

Plant Facility

500 Pullman Road Unit B

Edgewater, Florida 32132

Phone

(201) 820-2055

President Joseph Fazio Cell #

(201) 321-5797

Fax

(201) 845-7038

Email

jfazio@piwsinc.com